- V.V. Uglov, N.N. Cherenda, V.M. Anishchik, V.M. Astashynski, N.T. Kvasov. Materials modification by compression plasma flows action // Minsk: BSU. – 2013. 241 p. (in Russian).

- M.M.Kuraica, V.M.Astashynski, I.Dojcinovic and J.Puric. Modification of solid surface by a compression plasma flow // The book "Physics of Laser Crystals", editors J.-C.Krupa and N. Kulagin. Kluwer Academic Publishers. – 2003. – Chapter 16, p. 245-255.

- N.N. Cherenda, N.V. Bibik, V.V. Uglov, V.M. Astashynski, A.M. Kuzmitski. Formation of Al-Cr intermetallic inclusions in surface layer of eutectic silumin by plasma action. // Physics and Chemistry of Materials Processing. – 2013. – №1. – С. 37-43 (in Russian).

- V.M. Astashynski, I.L. Doroshevich, N.T. Kvasov, Yu.A. Petukhov, A.V. Pun’ko, and V.V. Uglov. Radiation Stability of Nanoscale Ferromagnetic Memory Elements// Journal of Surface Investigation. X_ray, Synchrotron and Neutron Techniques. – 2013. – Vol. 7, No. 1 – P. 85–89.

- V. M. Astashynski, E. A. Kostyukevich, A. M. Kuzmitski, A. A. Mishchuk, P. N. Shoronov. Interaction between oppositely directed compression plasma flows // Journal of Applied Spectroscopy. – 2012. – Vol. 79, Iss. 4. – P. 610-615.

- V.V. Uglov, R.S. Kudaktsin, Yu.A. Petukhou, N.T. Kvasov, A.V. Punko, V.M. Astashynski, A.M. Kuzmitski. Mass- and heat transfer in “metal layer - silicon substrate” system under the action of compression plasma flows // Appl. Surf. Sci. – 2012. – Vol.258, No.12. –Р.7377-7383.

- N. N. Cherenda, V. I. Shymanski, V. V. Uglov, V. M. Astashinskii, A. M. Kuz’mitskii, N. N. Koval’, Yu. F. Ivanov, A. D. Teresov. Formation of Zirconium–Titanium Solid Solutions under the Action of Compression Plasma Flows and High-Current Electron Beams // Inorganic Materials: Applied Research. – 2012. – Vol. 3, No. 5. – P. 365–370.

- N.N. Cherenda, V.I. Shimanskii, V.V. Uglov, V.M. Astashinskii, and V.A. Ukhov. Nitriding of Steel and Titanium Surface Layers under the Action of Compression Plasma Flows // Journal of Surface Investigation. X_ray, Synchrotron and Neutron Techniques, 2012. – Vol. 6, No. 2 – P. 319–325.

- V.M. Astashinskii, A.M. Kuz’mitskii, A.A. Mishchuk. Dynamics of formation of the compression plasma flow in a miniature magnetoplasma compressor // Journal of Engineering Physics and Thermophysics. – 2011. – Vol. 84, iss. 5. – С. 1102 –1107.

- V.M. Astashynski, A.M. Kuzmitski, A.A. Mishchuk. Dynamics of the interaction between plasma flows generated by a miniature magnetoplasma compressor and a target // Journal of Applied Spectroscopy. – 2011. – Vol. 78, Iss. 3. – P. 377-382.

- N.G. Galkin, V.M. Astashynski, E.A. Chusovitin, K.N. Galkin, T.A. Dergacheva, A.M. Kuzmitski, E.A. Kostyukevich. Ultra high vacuum growth of CrSi2 and β-FeSi2 nanoislands and Si top layers on the plasma modified monocrystalline silicon surfaces // Physics Procedia. – 2011. – V. 11, N 1. – 39–42.

- N. N. Cherenda, V.V. Uglov, M.G. Poluyanova, V.M. Astashynski, A.M. Kuzmitski, A.D. Pogrebnjak, B. Stritzker The influence of the coating thickness on the phase and element composition of a Ti coating / steel system surface layer treated by a compression plasma flow. // Plasma Processes and Polymers. – 2009. – Vol. 6, Issue S1. – P. S178 – S182.

- V.M. Astashynski, S.I. Ananin, E.A. Kostyukevich, A.M. Kuzmitski, V.V. Uglov, V.M. Anishchik, N.N. Cherenda, A.K. Stalmashonak, Yu. V. Sveshnikov, N.T. Kvasov, A.L. Danilyuk and A.V. Punko. Comprehensive modification of semiconductors and metals providing new structural features of surface layers subjected to compression plasma flows // High Temperature Material Processes. – 2007. – V. 11, N 4. – P. 536 – 548.

- V.M.Astashynski, S.I.Ananin, V.V.Askerko, E.A.Kostyukevich, A.M.Kuzmitski, А.A.Mishchuk, M.M.Kuraica, I.P.Dojcinovic, J.Puric. Studies and characterization of quasi-stationary compression plasma flows generated by gas-discharge and erosive plasma accelerators // Publications of the Astronomical Observatory of Belgrade. – 2007 – V. 82 – P. 23–33.

- V.M.Astashynski, S.I.Ananin, A.S.Emelyanenko, E.A.Kostyukevich, A.M.Kuzmitzky, S.P.Zhvavy V.V.Uglov. Bulk periodic structures formation on monocrystalline silicon surface under the action of compression plasma flows // Applied Surface Science – 2006. – V. 253, N 4. – P. 1866-1872. N. N. Cherenda, V.V. Uglov, V.M. Anishchik, A.K. Stalmashonak, V.M. Astashinski, A.M. Kuzmitski, G. Thorwarth, B. Stritzker. Modification of AISI M2 steel tribological properties by means of plasma mixing // Vacuum. – 2007. – V. 81, iss. 10 – P. 1337–1340.

- V.M. Astashynski, S.I. Ananin, V.V. Askerko, E.A. Kostyukevich, A.M. Kuzmitski, V.V. Uglov, N.N. Cherenda, V.M. Anishchik, Y.V. Sveshnikov, V.V. Astashinski, N.T. Kvasov, A.L. Danilyuk, A.V. Punko, Y.Pauleau. Deposition of nanostructured metal coatings on modified silicon surfaces in magnetoplasma compressor. // Vacuum. – 2005. V. 78, issue 2-4, pp. 157-160.

- V.M.Astashynski, S.I.Ananin, V.V.Askerko, E.A.Kostyukevich, A.M.Kuzmitski, V.V.Uglov, V.M.Anishchik, V.V.Astashynski, N.T.Kvasov, L.A.Danilyuk. Materials surface modification using quasi-stationary plasma accelerators // Surface and Coating Technology – 2004. – Vol. 180-181C, pp. 392-395.

- J. Puric, I. P. Dojcinovic, V. M. Astashynski, M. M. Kuraica and B. M. Obradovic. Electric and thermodynamic properties of plasma flows created by the magnetoplasma compressor // Plasma Sources Science and Technology. – 2004 – V. 13, No 1. – P. 74-84.

- V.M.Anishchik, V.V.Uglov, V.V.Astashynski, V.M.Astashynski, S.I.Ananin, E.A.Kostyukevich, A.M.Kuzmitski, N.T.Kvasov, A.L.Danilyuk, I.N.Rumianceva. Compressive Plasma Flows Interaction with Steel Surface: Structure and Mechanical Properties of Modified Layer // Vacuum, 2003. – Vol.70, iss. 2-3. – P. 269-274.

- V.V. Uglov, V.M. Anishchik, V.V Astashynski, V.M. Astashynski, S.I. Ananin, V.V. Askerko, E.A. Kostyukevich, A.M. Kuz’mitski, N.T. Kvasov, A.L. Danilyuk. The effect of dense compression plasma flow on silicon surface morphology. // Surface and Coatings Technology. – 2002. – V. 158-159C. – P. 273-276.

- V.V. Uglov, V.M. Anishchik, V.V. Astashinski, V.M. Astashinski, S.I. Ananin, V.V. Askerko, E.A. Kostyukevich, A.M. Kuz’mitski, N.T. Kvasov, and A.L. Danilyuk. Formation of Submicron Cylindrical Structures at Silicon Surface Exposed to a Compression Plasma Flow // JETP Letters. – 2001. – Vol. 74, No. 4. – P. 213–215.

- Astashinskii V.M. Formation of Compression plasma Fluxes of a Given Composition in Dense Gases // Journal of Applied Spectroscopy. – 2000. – V.67, N 2. – P.312-319.

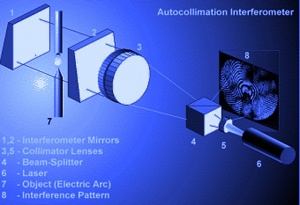

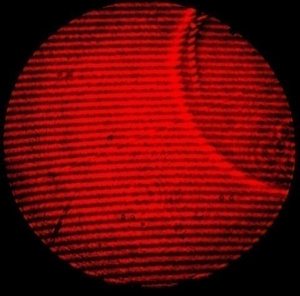

- Ananin S.I., Astashinskii V.M., Kostyukevich E.A., et al. Interferometric Studies of the Processes Occurring in a Quasi-Steady High Current Plasma Accelerator // Plasma Physics Reports. – 1998. – V. 24, N 11. – P. 936-942.

- Ananin S.I., Astashinskii V.M. Structure of a plasma flow in quasisteady high-current accelerators with a penetrable cathode transformer // Plasma Physics Reports. 1998. – V. 23, N 1, – P. 37-40.

- V.M. Astashinskii, G.I. Bakanovich, A.M. Kuz'mitskii, L.Ya. Min'ko. Choice of operating conditions and plasma parameters of a magnetoplasma compressor // Journal of Engineering Physics and Thermophysics. – 1992. – Vol. 62, Iss 3. – P. 281-284.

- Astashinskii V.M., Man'kovskii A.A., Min'ko L.Ya. et al. Physical processes responsible for the different operating regimes of quasistationary high-current plasma accelerators // Sov. J. Plasma Phys. (Engl. transl.) – 1992 – Vol. 18, No. 1. – P. 47-51.

- Astashinskii V.M., Efremov V.V., Kostyukevich E.A. et al. Interference-shadow studies of the processes in a magnetoplasma compressor // Sov. J. Plasma Phys. (Engl. transl.). – 1991. – Vol. 17, No. 9. – P. 545-548.

- V.M.Astashinsky, E.A.Kostyukevich, A.M.Kuz'mitsky, L.Ya.Min'ko. Interferometric stend with a laser source for investigation of plasma accelerators // USA. – 1990 – SPIE Proceedings. –V.1121. – P.650-654.

- Ananin S.I., Astashinskii V.M., Bakanovich G.I. et al. Study of the formation of plasma streams in a quasistationary high-current plasma accelerator // Sov. J. Plasma Phys. (Engl. transl.). – 1990. – Vol. 16, No. 2. – P. 102-108.

- V.M. Astashinskii, G.I. Bakanovich, E.A. Kostyukevich, A.M. Kuz'mitskii, A.A. Man'kovskii and L.Ya. Min'ko. Effects on compression-flux parameters from discharge characteristics in a compact magnetoplasma compressor // Journal of Applied Spectroscopy. – 1989. – Vol. 50, No. 6. – P.549-552

- Astashinskii, V.M. and Kostyukevich, E.A. // Sov. J. Plasma Phys. (Engl. transl.). – 1981. – Vol. 7. – P. 282.

- V.M. Astashinskii, G.I. Bakanovich and L.Ya. Min'ko. Investigation of the dynamics of plasma formation and the formation of the compression region of a gas electromagnetic plasma accelerator // Journal of Applied Spectroscopy. – 1980. – Vol. 33, No. 4. – P. 1061-1064.

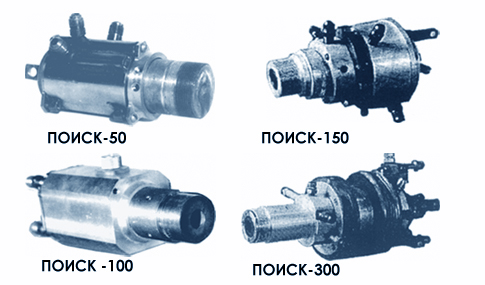

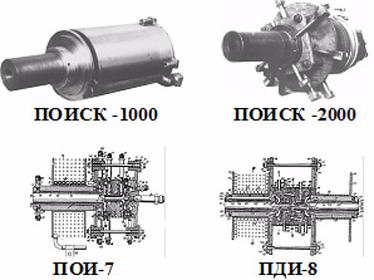

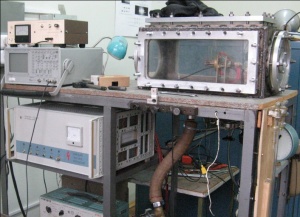

Several models of quasi-stationary high-current plasma accelerators of a new generation were developed in the Laboratory of Plasma Accelerators Physics. These plasmadynamic systems operate in the ion current transfer mode and provide the ion-drift acceleration of magnetized plasma. Our installations generate high-energy compression plasma flows of specified composition and on a set of parameters (plasma velocity – 50 ÷ 200 km/s, temperature and concentration of charged particles – (40 ÷ 200)•103 K and 1016 ÷ 1018 cm-3 accordingly, discharge duration – 100 ÷ 500 microseconds) surpass all other available types of plasma accelerators.

Main Research Directions

- Physics of quasistationary high-current plasma accelerators generating high-energy compression flows with plasma velocities of up to 200 km/s; the elaboration of principles for accelerating the macroparticles and heterogeneous plasma flows in such systems.

- Разработка и создание квазистационарных газоразрядных и эрозионных плазмодинамических систем различного целевого назначения, в том числе плазменных микродвигателей космического назначения. The development of new quasi-stationary gas-discharge and erosive plasma accelerators for various applications, including aerospace plasma micro-thrusters.

- The development of novel plasma methods for substantial improvement of surface properties of various materials exposed to compression plasma flows, which makes it possible to implement principles for a new scientific trend under development – surface plasma metallurgy

- The compression plasma flow-assisted synthesis of texturized submicron and nanoscale structures and formations, nanostructured metallic, dielectric, and metal-carbon coatings and thin films at a surface of semiconductor wafers

- The development of optical interferometers with a large viewing field and optical pressure sensors, the implementation of optical schadowgraph-interferometric and spectroscopic methods for diagnostics of plasma flows

- The numerical simulation of physical processes in quasi-stationary plasma accelerators and the plasma flow-surface interaction

Main Research Lines

- Study of processes of electric arc heating of gases and gas mixtures, designing and manufacturing of electric arc plasmatrons with the power from 50 kW to 3 MW and more that generate technology-required oxidative, reducing or neutral plasma

-

Development of fundamentals and methods of creating plasma equipment and large-scale technologies in metallurgy, plasma chemistry, industry of heat-insulating materials and utilization of man-made, domestic , and medical waste

- Perfection of the methods of treating toxic and radiation waste; application of new processes in production of heat-insulating materials and synthesis of nanostructures

- Systemic many-factor study and calculation of plasma and other systems (engineering objects, technologies and materials) by computer synthesis-technologies

- Investigation of the processes of heating and ablation of different-class composite materials; study of their thermal-strength and thermal-physical properties over a broad range of temperatures and heat fluxes, chemical composition and pressure of environment pressure, heating velocities; modeling of natural operating conditions of heat-protection elements of aircrafts of rocket-space technology

- Investigation of the synthesis of carbon nanostructures in the electric arc discharge of the co-axial magnetic field-applied plasmatron

-

Study of the erosion of coatings (materials) in high-temperature gas-dust flow as applied to solid-fuel furnace devices of heat and power plants

Determination of heat conduction of heat-insulating materials at high temperatures - Development of technologies of applying protection coatings made of different adding materials over the elements of machines and mechanisms by the electric arc spraying

Basic Developments

Development and implementation of principally new plasma technologies in chemical, metallurgical, and metal-working industry:

- Process of producing acetylene and technical hydrogen from natural gas in hydrogen plasma

Plasma production of super-and ultra-thin mineral microfibers from glass and basalt - Metallurgical process of direct production of steel from iron-ore pellets using low-temperature plasma

- Process and the instrumentation of the process of producing hollow glass microbeads and microspheres in the gas torch jet

- Process and the instrumentation of the plasma process of obtaining hollow ceramic microspheres from corundum

- Making of plasmatrons for plasma cutting of sheet metal materials

- Development of high-efficient plasma reactors of different type: co-current, cylindrical, profiled counterflow, single- and multijet that allow lump and power-like materials, and dispersed solutions to be treated

- At the Laboratory high-efficient quenches, feeders for supply and batching of powder-like materials, injectors for dispersion of solutions and suspensions, as well as other equipment are being designed for the instrumentation of plasma processes

- The Laboratory elaborates the designing documents on plasma plants, systems of their energy supply, makes installation, adjustment and alignment works, as well as provides backup service

- Unique computer synthesis-technologies for investigation, designing and optimization of technological processes and plants with regard to the fact that the processes are multi-criterion, multi-parameter, nonlinear and stochastic, have no world analogs

- Methods for visualization of the solution of the synthesis problem in the form of topological structures of the appropriate projections of a multidimensional space of governing parameters

- Procedural model of an engineering system of computer debugging of pilot samples of operational plasmatrons. The method of multidimensional design synthesis was used in trend computer calculations that allow estimating the efficiency of the procedures of attaining a required quality of an object to be made that were proposed by developers;

- Bench for resetting the elements of machines and mechanisms