Main directions of the activity

- Perfomance of scientific – research works in the field of formation of surfans by realization of the mass-transfer effect namely the ablation of a surface in the process of its working with energy transfer

- Investigation of nanowear process, threebological and mehanoсhemical interactions.

- Search for technical equipment and technologies for high-accuracy working of the surfaces of parts of optical, semiconductor, and other devices as well as analysis, development, production testing, and adoption of them industry

- Development of effective designs of equipment and their attachments for working of flat convex and concave parts of devices including large-size onesб and production of these equipment

- Search for rheological liquids for polishing of hard superhard chemically austable water –soluble and nanostructured materials including thin films and coatings and development of their compositions

- Development of algorithms control means and a softwace for realization of formation of rheological liquids and their application

- Perfomance of contact and contactless complex control over the state of surfaces befor and ofter their working Use of the results of this control for determing the technological parameters of the formation of surfaces and their polishing

ЕXPERIMENTAL BASIS

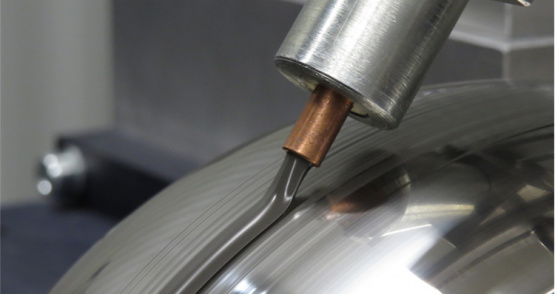

- Laboratory setup for polishing

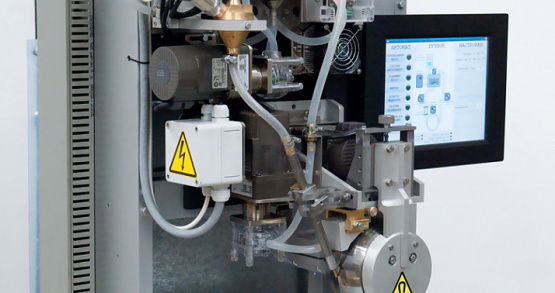

- Complex for formation and polishing of products with a sire as large as 420 mm

- Two-dimensical and three-dimensional modules for working of products with sizes as large as 2,5 м

- IKD-110 3D interferometer

- KLA-Tensor MicroXAM-800 profilometer Developments

DEVELOPMENTS

Technologies and equipment for hight-precision formation and magnetic-rheological polishing of flat, spherical, and aspherical surfaces of precision parts:

- Technologics of formation of surfaces and their polishing

- Special facilities for formation of surfaces and their polishing

- Modules increasing the technological capabilities of equipment

- Polishing compounds for finishing treatment of surfaces

- Software

- Complex diagnostics of the state of surfaces

Examples of application of developments proposed

- Formation of the asphercal surface of an optical product that was initially spherical in shape

- Automated working of local regions of a surface with different dimensional allow ances (retouch regime)

- Removal of a very thin defect layer formed in the previons operations for increasing the radiant strength of optical elements of laser systems, including products of water-soluble crystals

- Finising treatment of the surfaces long-length tubes ganges complex joints and precision guides made of nonmagnetic metal alloys

- Planarization of the surfaces of integrated circuits of complex morphological nd topological designs for production of 3D electronic elements

- Polishing of large-size optical elements, mirrors and their segments made of zerodur, glassuramics and silicon carbide

Advantages

Overall sizes of products are from 3mm to 2.5 m the meansquare exactness of the shape of a surface is as high as λ/100, and its meansquare roughness Rq = 0,2-2,5 nm

The full automation of the working of a surface provides a hight repeatability of the results obtain for both separate regions of a product and a series of pieces

Overall sizes of products are from 3mm to 2.5 m the meansquare exactness of the shape of a surface is as high as λ/100, and its meansquare roughness Rq = 0,2-2,5 nm

The full automation of the working of a surface provides a hight repeatability of the results obtain for both separate regions of a product and a series of pieces