Specific Characteristic

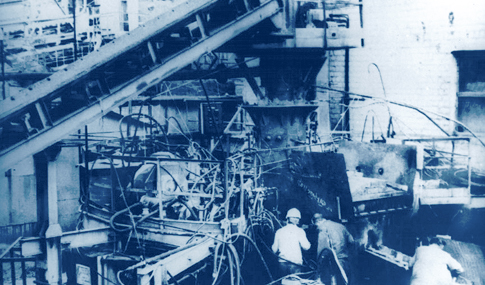

Technical performance of the production process at the plant of the Dnepropetrovsk Metallurgical Works (20 thousand tons steel per year): installed electric power – 3000 kW, total power of plasmatrons mounted in the shaft and the post reduction bath – 1800 kW, power of a single plasmatron – 300 kW, number of plasmatrons in the shaft – 3, number of plasmatrons in the post reduction bath – 3. Plasma-forming gas – mixture of natural gas (coal gasification products can be used) and oxygen. Oxygen-to-natural gas ratio α = 0.5 ÷ 0.3. Specific energy consumption per 1 ton steel: consumption of iron-ore pellets – 1.546 ton, reducing gas mixture flow – 1200 m3, electric energy consumption – 750-800 kW·hr/t.

Intellectual Property

Metallurgical plasmatron patents. Design documentation. Process technical documentation. Specific know-how. Plasmatron design prototypes. Operating regimes.

Prospective Nature of Investment Project

1. Making one-off devices under contracts with the customer.

2. Organizing the enterprise for equipment of metallurgical works with plasmatron facilities.